GASKET INDUSTRIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to GASKET INDUSTRIES

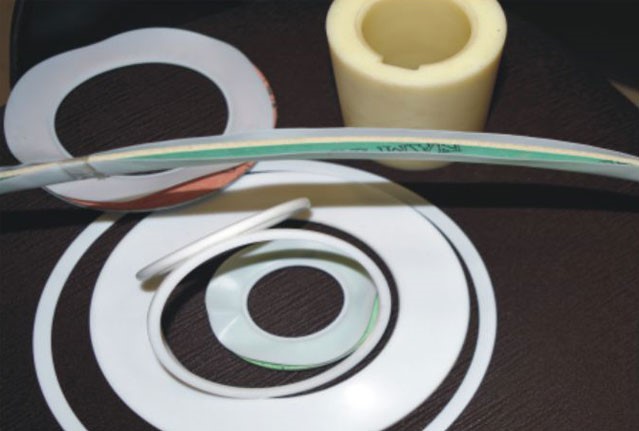

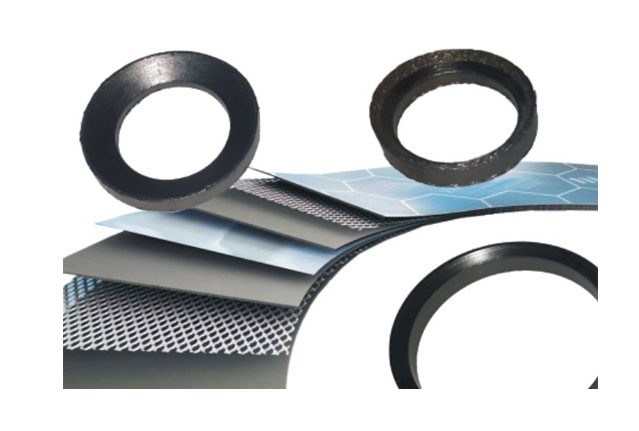

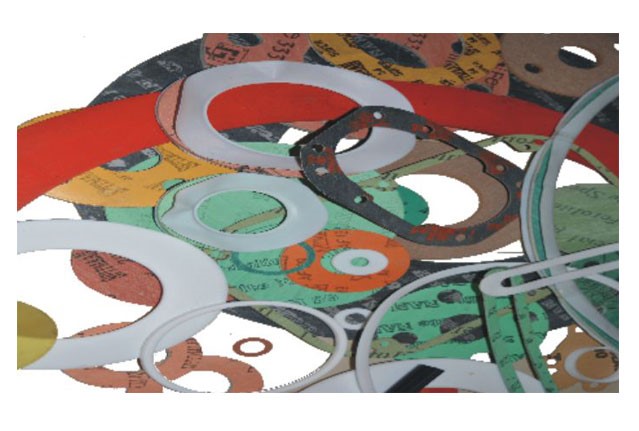

Flange Insulation Gasket Kit

An effective form of controlling losses due to corrosion. They can be used to control stray electric currents in piping at oil, gas, water, refinery and chemical plants and increase the effectiveness of cathodic protection systems and confine or eliminate electrolytic corrosion. Most common components being a Gasket, Sleeves for bolt protection, and washers for nut protection. The variety of component materials is dependent upon application.

Type “E” gaskets have the same outside diameter as the flange offering full protection. This will prevent the collection of foreign matter between the flange faces and ensures complete cathodic isolation. A wide variety of materials are available to suit the requirements. Type “F” gaskets are made to fit inside the bolt circle and cover the raised face portion. It is recommended that a dirt guard be used to prevent foreign matter from shorting out the flanges. The flanges can also be wrapped. A wide variety of materials are available to suit the requirements. Type “D” or RTJ gaskets are made to fit the ring groove on ring type joint flanges. Usually manufactured from phenolic based materials. Gaskets Type E and F can be manufactured from: · Phenolic (plain and neoprene faced) · GRE (Glass Reinforced Epoxy) · Asbestos sheet gasket · Non Asbestos Material · Special Elastomers .

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.